Flexible Packaging

One unique concept. Endless possibilities

Flexible packaging is the right choice for many reasons. The material is great for extending shelf life and it is lightweight which is an advantage when it comes to the logistic parameters. Combining these options with the unrivaled Schur Star machines you will get a high efficient and optimized packaging process - and a holistic solution to match your product.

Three reasons to choose flexible packaging from Schur

1. Versatility

You can run different bag sizes and products on the Schur Star machine. Change-over is quick - both when it comes to bags and products. In addition, bag intake, opening, filling, sealing and marking can be handled manually or automatically, or configured for a hybrid setup.

2. Efficiency

The premade bags tailored to your product specifications are delivered on a unique string. All machineability issues are already solved, so the bags run and fill consistently: no drips, no spills, no downtime. In other words: You will experience a smooth operation with high capacity.

3. Decency

At Schur, we foster partnerships, leading to long-term relationships focused on long-term success for all involved. With more than +65 years of experience with flexible packaging, we know that one size does not fit all, and we know that the starting point for a great result is your need.

Let's make flexible packaging part of the solution.

Bagging technology made simple with our Schur®Star Bags

-

Barrier qualities for any need

-

Reclosable zipper and large fill opening

-

Multiple bag formats without tool changes

-

Versatile usage for different industries

-

Bags are linked together = smooth bag intake

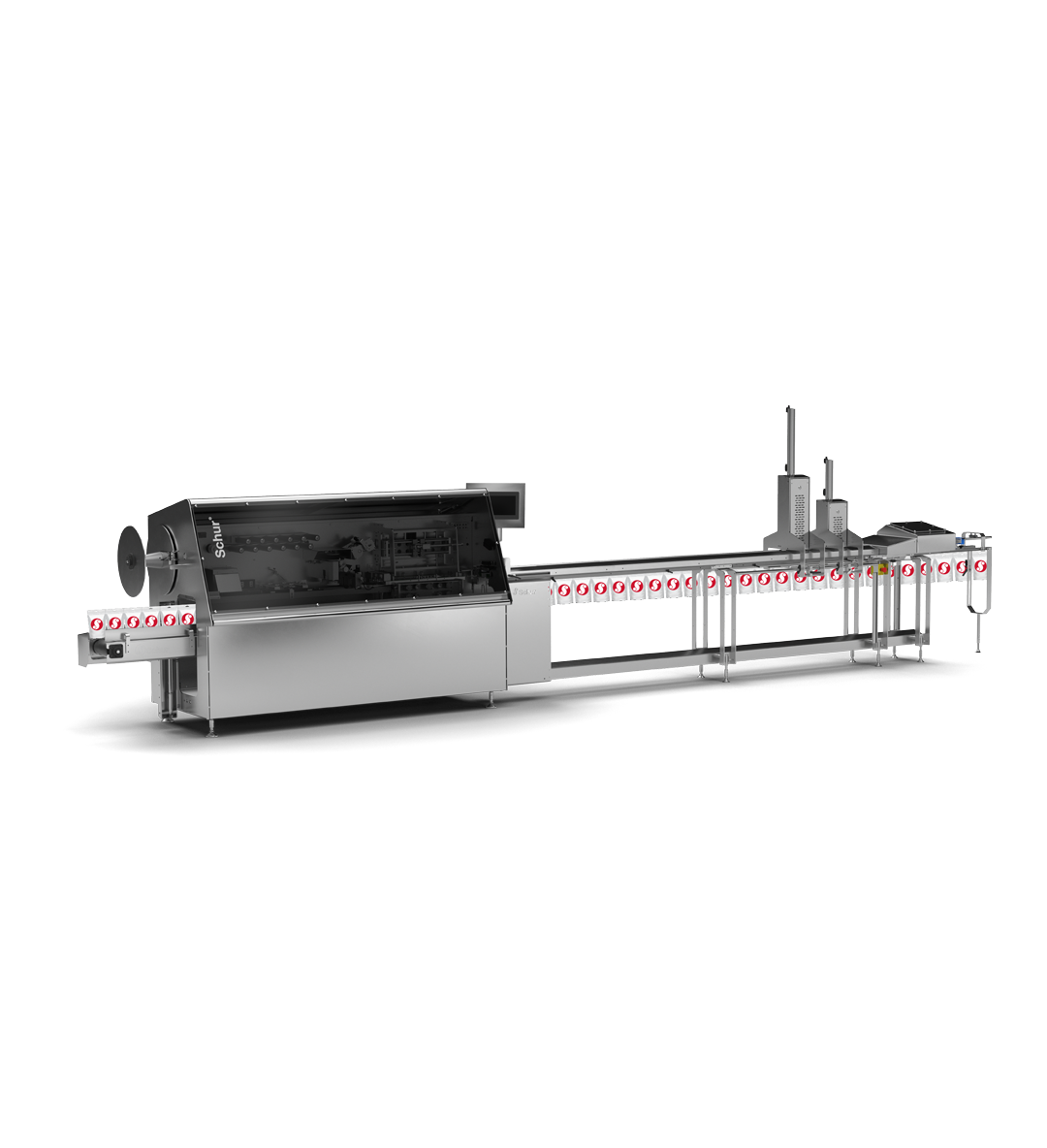

The Schur®Star Packaging Machine

-

You can run different formats without any extra tool costs

-

Quick change over and the option to run small series

-

Optimize production resources

-

Multiple filling options

-

Easily to integrate into an existing production setup

-

Easily to combine with other equipment

We've helped more than 500 companies with a Schur®Star Concept

No setup is identical as everything is tailormade for your business and your needs. Learn more about our Schur Star concept right here.

In Australia, we support our clients with rollstock

Our portfolio of rollstock material is versatile and we can find a solution for any needs. Our flexible packaging rewind fits a wide selection of applications, and our material is designed to enhance packaging performance in all markets.

Speak with one of our experienced Schur®Star consultants.