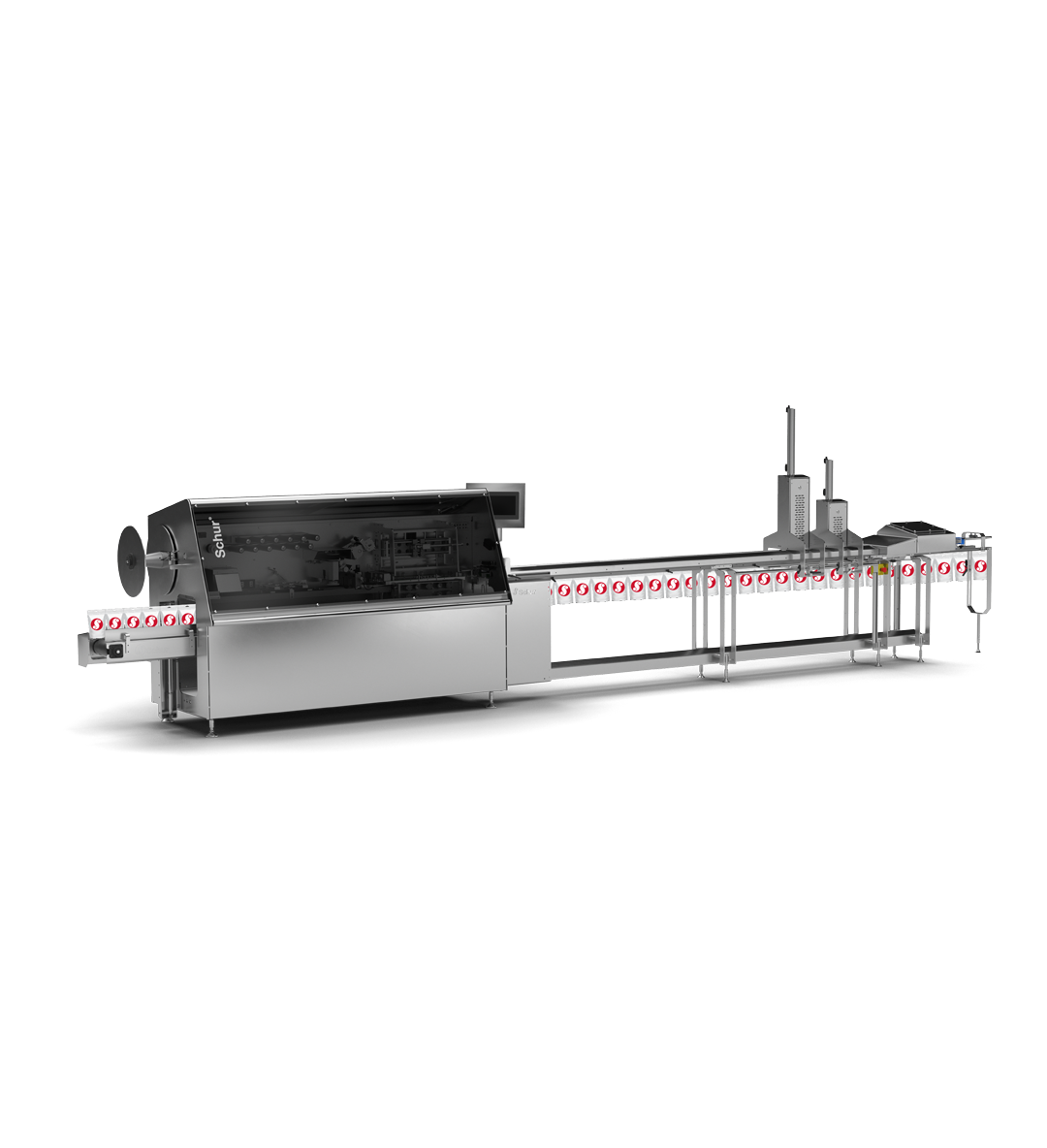

Schur®Star

Bagging technology made simple

The idea behind the Schur Star concept has been to make bagging technology simple. With years of know-how from the packaging industry, we always use your product as the starting point when creating a packaging solution. That is also why we offer two different platforms within the concept - a comprehensive solution and a more agile solution.

A range of opportunities

-

Barrier qualities for any need

-

Reclosable zipper and large fill opening

-

Multiple bag formats without tool changes

-

Versatile usage for different industries

-

Bags are linked together = smooth bag intake

-

Different sustainable solutions

Endless possibilities!

-

You can run different formats without any extra tool costs

-

Quick change over and the option to run small series

-

Optimize production resources

-

Multiple filling options

-

Easily to integrate into an existing production setup

-

Easily to combine with other equipment

Speak with one of our experienced Schur Star consultants.